Welcome to Burvills, where precision cutting is the hallmark of our metalwork creations.

Our commitment is to deliver stunning, timeless pieces that captivate and endure. To maintain our position as pioneers in bespoke craftsmanship, we relentlessly seek innovative technologies that enhance efficiency and elevate the uniqueness of our products.

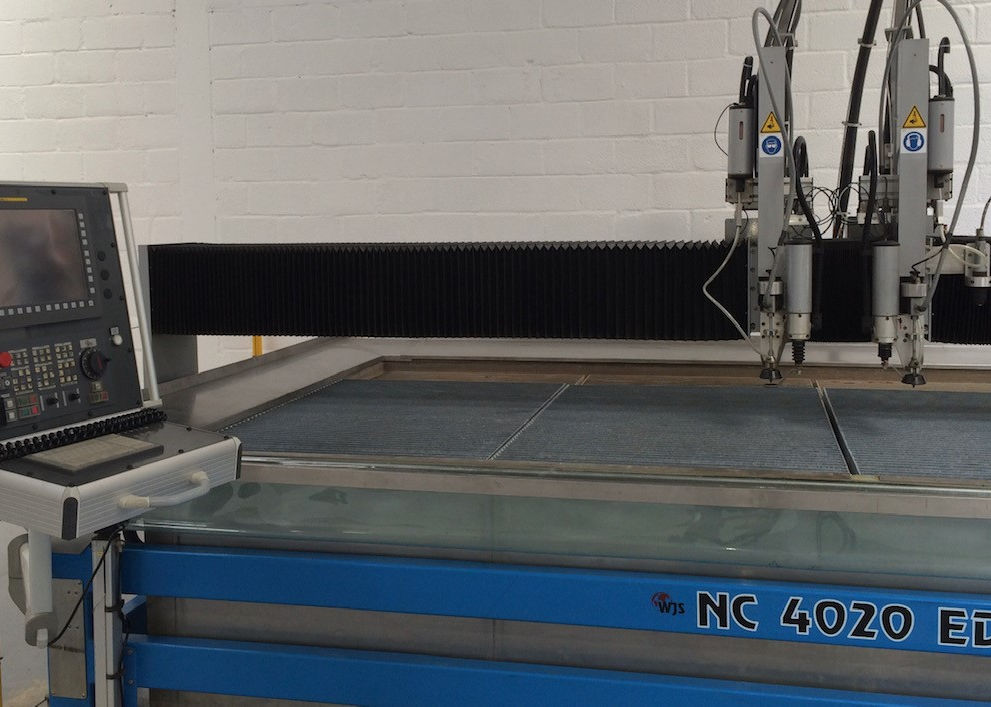

In this article, we invite you to discover the extraordinary capabilities of one of our services, the CNC water jet cutting machine, which is a true gem in our workshop.

Let’s dive in.

The Science of Water Jet Cutting

Let’s begin by unveiling the science behind water jet cutting – a highly precise method that employs a high-pressure jet of water to carve through various materials.

To enhance its cutting power and ensure cleaner results, we often add abrasive substances, such as sand, to the water.

This exceptional technology enables us to achieve extraordinary precision and depth, effortlessly cutting through metals up to 20cm thick. The benefits of water jet cutting are abundant, including unparalleled versatility and the ability to achieve intricate designs with absolute accuracy.

Additionally, this environmentally friendly process produces no hazardous materials, dust, or fumes.

The Burvills Water Jet Cutting Package

Few companies in the South East can match our comprehensive water jet cutting service at Burvills. We take pride in being at the forefront of precision profile production methods, and we are thrilled to offer this unparalleled service to our esteemed clientele throughout the UK. Our water jet cutting package comprises three key steps:

- Design: When you partner with us, we transform your envisioned product into a vivid reality. Utilising our state-of-the-art Solidworks software, we create a 3D image that brings your concept to life. Each step of the design process is conducted in close consultation with you, ensuring your involvement in the creation of the product right before your eyes.

- Computer Generated Images (CGI): We understand the importance of visualizing the placement of your metalwork. Through our CGI technology, we seamlessly integrate the images of our creations, generated in step one, into your desired location. This allows you to witness and approve the final look, providing an opportunity for any last-minute adjustments.

- Cutting: Once you are satisfied with the design and CGI, it’s time to initiate the cutting process. Our software follows the pattern we meticulously crafted, utilising super stream technology to execute precise cuts at various grades. While the machine ensures top-notch quality, our experts conduct a manual check to guarantee an impeccable final product.

The Benefits of Water Jet Cutting

Let’s delve deeper into the multitude of advantages offered by our water jet cutting machine:

Cost-effectiveness

Water jet cutting is an economically advantageous process, as it minimises material wastage. Additionally, its clean cuts eliminate the need for additional labor-intensive tasks like sanding. By implementing sustainable water practices, such as responsible sourcing, water becomes an even more cost-saving resource.

No Heat Distortion

Unlike other cutting methods that involve heat, water jet cutting eliminates the risk of material distortion. The absence of extreme heat allows our products to maintain their shape flawlessly, ensuring the preservation of precise cuts and design integrity. This eradicates the need for additional measures to mitigate heat-related issues, resulting in impeccable craftsmanship.

Versatility

While our primary focus is metalwork, water jet cutting exhibits remarkable versatility, extending its capabilities to materials such as plastic, glass, and stone. With the ability to achieve precision cuts at various depths, we have expanded our cutting capabilities, bringing intricate designs to life.

Ultimate Precision

Water jet cutting is synonymous with unparalleled precision. Our cutting machine boasts accuracy within 0.2mm, enabling us to execute a wide range of designs with exceptional results. Our software minimises the risk of errors, utilising precise programmed patterns to set the machine in motion. Stringent quality monitoring ensures a meticulous replication of the intended design down to a remarkable 0.2mm.

Renewable Materials

Water, our chosen cutting medium, aligns with sustainable practices. Thanks to the precise nature of water jet cutting, wastage is kept to a minimum. We are committed to responsible water practices, utilising water efficiently and responsibly, making this method an excellent choice for the environment. Additionally, water jet cutting reduces the release of fumes into the atmosphere, setting it apart from alternative cutting methods.

Unparalleled Metalwork from Burvills

If you aspire to embrace the extraordinary capabilities of our stunning water jet cutting machine, we invite you to get in touch with our esteemed team at Burvills today. Together, we will bring your ideas to life and create a bespoke metalwork masterpiece that perfectly aligns with your vision.

Want to know more? Then get in touch today.